about me

i first saw the light of this world in 2006.

it always facinated me playing around with all kinds of materials, from building mud houses with age 5 or doing controlled arson with 11 and smashing around on nails.then around 14 i went to a medival market and saw a blacksmith and tought like "This is litteraly the coolest thing ever"i spent along time with my new found inspiration, not knowing anything about knifemaking or blacksmithing and just kindoff winged it, played around with propane torches and angle grinders, didnt produce anything of use except fun and a growing passion :)roughly a year later, i bought myself my first and current anvil, it has a chipped corner but i love it. dug a little bit deeper into how knives work.after i finished school, i got drawn away from the steel to the woodworking. did a year of basic vocational training in woodworking. that craft runs deep in my family, probably the reason i love all kinds of woods and making handles!2024 i got the real deal of an beltgrinder after being sucked into the metallurgy and bladesmithing rabbithole.

so the real knifemaking journey began :)

please contact me for purchase inquiries

all prices are without shipping!i use stabilized handle material for almost all my handles, means i wont mention it in every post :)for more information/pictures from the knives please contact me or visit my instagram

email: [email protected]

"the bog morning"

c130 180x50mm harpoon bunka with hamon, bog elm -330€

collab with felix diemling, 160x43mm keyhole sanmai 80crv2core, -600€

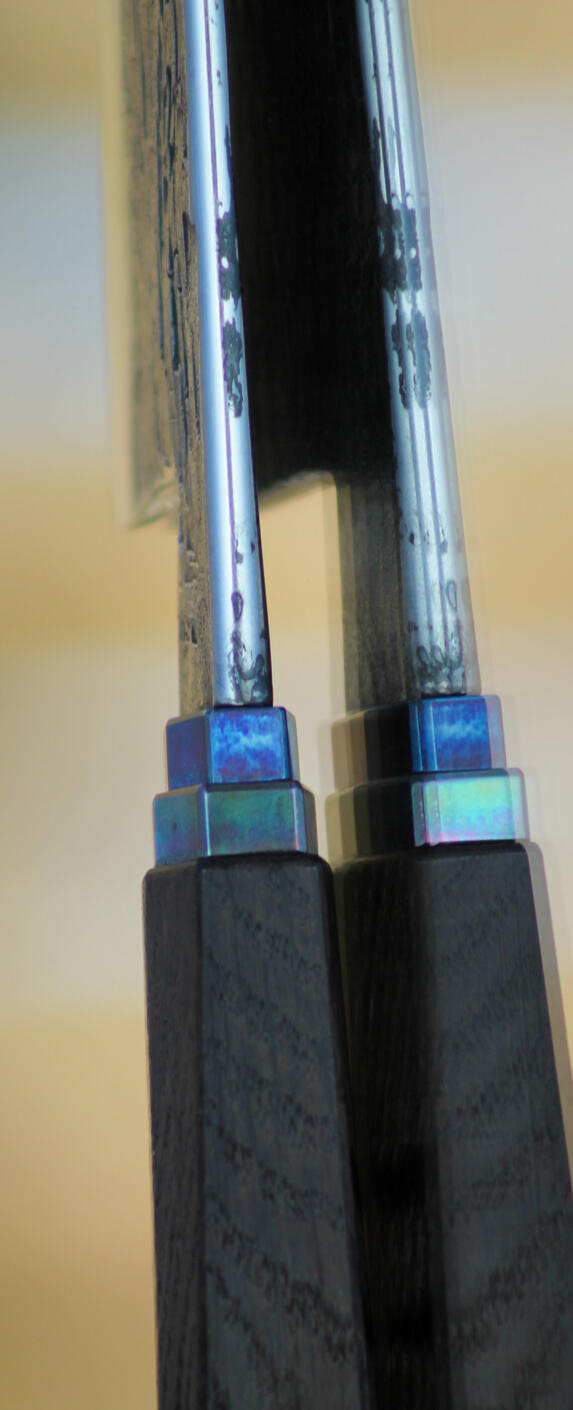

first stone polish, forged with glatt knives shop/style , 220x70mm 02/15n20 damascus core, wrought clad with titanium hardware -910€

52100 245x65mm workhorse in shipwreck theme -SOLD

52100 70x26mm integral petty with x cut mango handle -195€

15n20/O2 damascus 110x28x7mm pukko, titanium, curly narra, i can make a sheath on request -450€

c130 145x60 nakiri for right hander, hollow forged on right side, tansania blackwood -440€

how do i commission or buy a knife?

that´s pretty simple :)a rough idea in what direction it should go, is always good but not necesary. i´m sure we can make something work!also feel free to contact me with any questions!

email: [email protected]

impressum

Lorenz Schulzeschützenberg 506317 seegebiet mansfelder landGermany

care instructions

DOS

-Maintain the sharpness of your knife on a regular basis. Use a very fine and high quality honing steel rod or a leather strop idealy loaded with a compound, for maintenance. High grit water stones if dull.

- If the edge of your knife feels too thick after some time, don't hesitate to thin it. It's a tool meant to perform.

- Use your knife for what it was made ( do not chop bones or pumkin with a fileting knife)

-To keep your handle sealed from moisture, occasionally apply natural oils such as boiled linseed oil or hardwax oil. (not needed for synthetic handles)

-When the work is done, wash your knife with clear water and dry thoroughly.

-use the knife on preferably wood or plastic cutting boards

-Love your knife, have fun working with it, and use it with care :)DON'TS

- Don't ever use your knife on hard surfaces like ceramic, glass, stone or steel.

- Don't put your knife in a drawer together with other knives or hard materials.

- Don't put your knife into a dish washer - no matter how dirty it is.

- The edge of your knife comes very thin and the steel is very hard - cut with care. Don't ever jam your knife in hard foods nor in soft wooden or plastic boards or twist the blade. This may result in damage to the edge.

- Your knife is made from carbon steel (non-stainless steel). Don't let it lie around for too long after use especialy acidic foods/all moisture. It will result in rust.

- Don't use your knife for other purposes than cutting food. It's a high performance tool designed for a special task and not made to withstand abuse.

- Don't hurt yourself.